Applications for Embedded & IoT devices

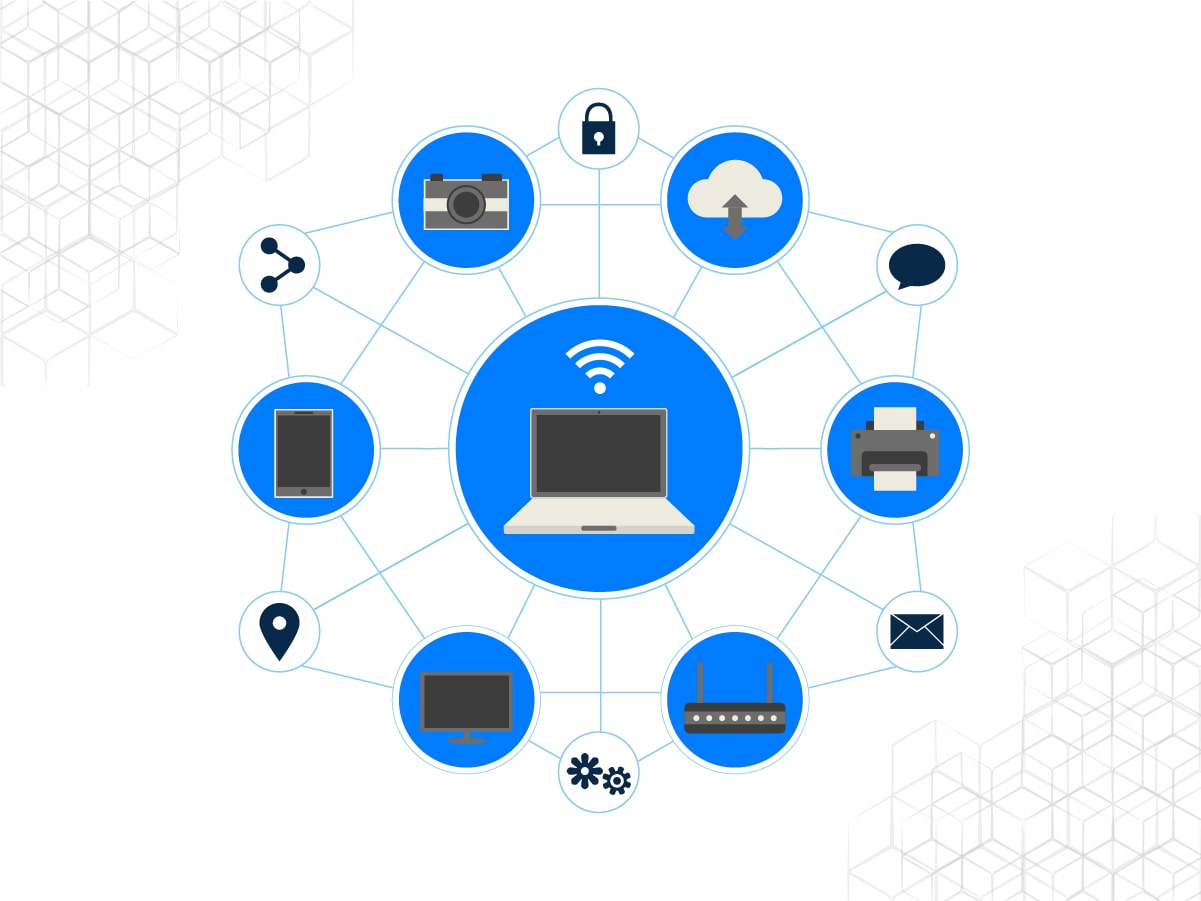

In the domain of IoT and embedded systems, our software applications are essential. They deliver expert solutions perfect for manufacturers who need to manage data collection, communication, and visualization in embedded devices.

Our comprehensive software suite includes a flexible framework and a communication engine designed for interoperability with devices using COM ports, USB, Bluetooth, Wi-Fi, and other standard connectivity options.

For data visualization, our framework adheres to CFR Part 11 regulations, equipped with secure access controls, comprehensive audit trails, and detailed reporting features indispensable in the medical and laboratory device industries.

IoT & Embedded Systems: Get Instant Insights, Powerful Analysis & Easy Device Control

Benefits of IOT and Embedded Systems

Enhanced Operational Efficiency

IoT and embedded systems boost operational efficiency through process automation and workflow optimization. Smart devices and sensors help communicate coherently among diverse parts of an operation, making room for real-time monitoring and management. Think of it: at the manufacturing floor, IoT devices would oversee the production lines, modulate their operation according to demand, and predict failures well ahead of time so that downtimes could go out the door. Such a degree of automation can not only hasten the production process but, at the same time, reduce the possibility of human errors taking place in the production process, which eventually assists in attaining consistent and reliable output. This, therefore, allows businesses to increase productivity with minimal costs incurred from operations, allowing them to be competitive and operate efficiently.

Real-Time Data and Analytics

IoT devices gather real-time data and, more importantly, send the same. This means businesses can get on-the-go insights since the embedded systems in IoT devices process collected data and hence can make analyses and respond immediately. Such a capability should be critical for those industries where exigencies change, such as logistics and healthcare. Real-time data on the position, traffic conditions, and weather for logistics companies will either optimize routes or expedite delivery times. The real-time monitoring of patient vitals in the health care sector will ensure patients receive their interventions on time, hence, a good outcome for the patient. This will sharpen organizational capability toward superior operational efficiency, superior market change response, and superior customer need adaptability, enabling proactivity for innovation and growth through harnessing the power of real-time data analytics.

Cost Reduction through Predictive Maintenance

Predictive maintenance will be one of the most influencing benefits of IoT and embedded systems, bringing significant, adequate cost savings over olden-day, conventional approaches. Thus, equipment sensing with predictive maintenance will predict a breakdown before it occurs, so the organization will not incur huge costs due to downtime and emergency repair. They shall increase machinery life, save maintenance money, and avoid unplanned outages. In manufacturing, for instance, predictive algorithms will search for trends in historical as real-time data that will indicate forthcoming equipment failure. Maintenance can be scheduled conveniently during off-peak hours while production continues around the clock. This will save on repair costs and enhance an overall asset management strategy, contributing to a more sustainable business practice.

Improved Safety and Security

These are critical means—IoT and embedded systems for increased safety and security in many sectors. These devices allow an organization to be aware of the environment in real-time, allowing them to respond much quicker and more impactfully in case of an undesired event. The example of industrial setup IoT sensors can be used to sense conditions like gas leaks or equipment malfunctioning. This information can be sent to the operator inside the operating room promptly to prevent any potential accident. Concerning security, embedded systems in the cybersecurity field are solid and secure; they have all the required attributes of security that can be used to identify threats and control them before they affect the network. Building access controls also limit the number of authorized people who can enter some places. Generally, advanced monitoring via the IoT and proactive threat detection ensures that assets, data, and personnel are well protected, making them contribute to a safe operational environment.

Remote control and monitoring

IoT will enable industries to monitor and control their operations even when they are far away if the control of their operations covers extensive geographical locations. This will ensure continuous monitoring of the infrastructure and installed systems without being physically present, which can significantly reduce operational costs with improved efficiency. These include the ability of utility companies to oversee the real-time performance of electrical grids from a central control room and respond promptly to any issues that may arise. In addition, the solution in IoT could make it possible to monitor the soil moisture and crops, therefore making it possible to determine irrigation and fertilization decisions that the farmer can take without coming to the actual field. In this sense, remote monitoring and control provide businesses with efficiency, improved responsiveness, and flexibility for those who work in highly dynamic environmental conditions and meet market requirements.

Enable Increased Productivity and Automation

Automation driven by IoT and embedded systems can work miraculously to make the operation more productive with optimized workflow and less human intervention. It is a process that can do things repeatedly, accurately and reliably, which means human resources can focus on strategic activities instead of petty tasks. In the manufacturing sector, IoT-enabled robots can handle various tasks: assembly, packing, and quality checks. That means a faster production rate, again in conjunction with reducing the error margin. In an office setup, automated systems can control everything from temperature to lighting, creating optimum working conditions, which may increase the workers’ performance. Apart from this, the data collected by the Internet of Things gadgets keeps refining processes until there is assurance that operations are getting more efficient over time. On the other hand, this extra level of automation supports improved productivity and drives innovation since businesses could channel more time and resources into carrying out new ways of doing things or improving the current solutions.

Energy Savings and Environmental Sustainability

IoT and Embedded Systems are major technologies that allow energy to be saved and are environment-friendly technologies. They help to manage Smart Energy by the optimal use of resources. For example, IOT-connected heating, Ventilation, and air conditioning (HVAC) systems would use secured occupancy data and weather data to adjust their settings on a real-time basis, hence reducing huge wastes of unnecessary energy use. IoT sensors check the machines in case they are gobblin Energy Excessive energy, and it promptly notifies industrial needs, such as the units that are gobblin Energy excessive energy. In addition, the IoT finds its application in smart grids for more effective balancing of the electricity load and integral Energy renewable energy. IoT is an enabler. It helps businesses reduce energy levels and supports initiatives for green energy, thereby aiding them in pursuing a goal for sustainability for a better planet.

Better quality control

(IoT) and embedded systems will continue to enhance the quality level of products and the consistency achieved throughout manufacturing and production processes. The technology will allow production lines to be monitored in real-time at any point; that is possible through data analytics, whereby any quality deviation will be detected almost immediately after it has exceeded the set limits. The sensors can be of the product’s dimensions, temperature, humidity, and other key parameters that must be monitored to ensure that each product conforms to the rigid quality criterion before dispatch from the factory. The system also reduces the risks of pushing the market up to products with defects, as well as the costs from recalls and reworks. Control quality is paramount to safety in critical sectors such as food and pharmaceuticals. IoT in the industry assures compliance with health regulations and consumer safety standards. Better quality control mechanisms will bring customer trust and satisfaction, bolstering the brand name through competitive advantage.

Scalability and Flexibility in Operations

IoT systems provide unprecedented scalability and flexibility. They offer businesses a chance to quickly align their operations with changing market demand or, in the best scenario, business growth. A company can deploy more sensors and devices using modular IoT architectures, making it easy to scale out without necessarily overhauling the existing infrastructure. The scalability goes from applications where the facility is increased in a factory to produce more, including new services in smart cities. In addition, the IoT offers flexibility: it allows firms to test how new techniques or configurations impact their operations at a small scale and under their control before rolling out the entire deployment. Such flexibility is paramount to businesses that want to remain a few steps ahead in these fast-changing industries, as it allows for pivoting timeously and efficiently to capitalize on new opportunities while proactively nipping challenges in the bud.

Frequently Asked Questions

The Internet of Things (IoT) refers to the network of interconnected devices that communicate and exchange data through the internet. These devices, equipped with IoT and embedded systems, collect and act on data they acquire from their environments using embedded sensors, processors, and communication hardware. This network enables devices to interact, collaborate, and learn from each other’s experiences without human intervention, making systems smarter and more efficient.

IoT technology can significantly enhance operational efficiency by automating routine tasks and improving resource management. IoT and embedded systems provide critical real-time data that helps businesses make informed decisions quickly, leading to better productivity and reduced operational costs. Furthermore, these systems improve customer service by enabling more personalized interactions based on data-driven insights.

Embedded systems are specialized computing systems that form part of a larger system where they perform specific control functions within IoT and embedded systems. They are designed to handle specific tasks and are optimized for particular applications, often with real-time computing constraints. These systems are integral to various consumer, industrial, and healthcare devices, offering precise control and enhanced functionality.

Security in IoT solutions is paramount, and we implement several layers of protection to ensure data safety and system integrity in IoT and embedded systems. Our solutions use advanced encryption methods, secure communication protocols, and robust authentication mechanisms to protect against cyber threats and prevent unauthorized access to sensitive data.

IoT and embedded systems streamline operations by optimizing the use of resources and automating processes, which significantly reduces costs over time. They enhance asset management through continuous monitoring and maintenance, reducing downtime and extending the lifespan of equipment. Predictive maintenance capabilities also prevent costly emergency repairs by addressing issues before they escalate.

IoT technology finds applications across a broad spectrum of industries, enhancing efficiency and productivity wherever it is applied. Key sectors include manufacturing, where IoT and embedded systems optimize production lines; healthcare, where they enhance patient care; agriculture, where they improve crop management; logistics, where they streamline operations; and urban development, where they contribute to smarter city solutions.

IoT technologies enable businesses to offer more personalized and efficient services by leveraging real-time data to understand and predict customer needs and preferences. This allows companies to deliver targeted offers, improve service delivery, and engage with customers more effectively, leading to increased satisfaction and loyalty.

Yes, one of the greatest strengths of IoT solutions is their scalability. They can be easily adjusted and expanded to accommodate the growing needs of your business, from adding more devices and sensors to integrating new functionalities, ensuring that your IoT ecosystem evolves in line with your operational requirements.

Predictive maintenance is a technique enabled by IoT that uses data analysis tools and techniques to detect anomalies and predict equipment failures before they occur. This approach allows businesses to perform maintenance at just the right time, which minimizes downtime and extends the life of the equipment while significantly reducing maintenance costs.

The implementation duration of an IoT solution varies depending on its complexity and scope but typically takes anywhere from a few weeks to several months. We prioritize a strategic approach to deployment, working closely with our clients to ensure a smooth integration with existing systems and processes, and we provide thorough training to ensure all users are comfortable with the new technology.