In the manufacturing sector, data is the very core of any process. However, collecting data is only the first step. The real value is derived from transforming this type of data into information that can be used to optimize work processes, increase effectiveness, and foster innovation. Business intelligence in manufacturing is the link between raw data and the decisions that are made from it. This blog focuses on how BI transforms the manufacturing industry, leading companies from data chaos to innovative and strategic solutions.

Challenges in Manufacturing Without Business Intelligence

Lack of BI strategy poses challenges that most manufacturing companies encounter in their operations. These challenges include:

- Data Silos: Data is fragmented across departments which makes it difficult to gather and process it to get real insights.

- Inefficient Operations: It becomes almost impossible to determine areas of slow down or areas that require improvement when there is no real-time data.

- Poor Decision-Making: Instead of basing decisions on facts, people make educated assumptions and that results in inefficiency.

- Missed Opportunities: Some of the negative impacts include late identification of market trends or inefficiencies in production that may lower competitiveness.

- Inventory Issues: Deficient supply, inadequate inventory, or problems of supply chain management.

These problems highlight the importance of business intelligence in manufacturing to coordinate the management and utilization of information.

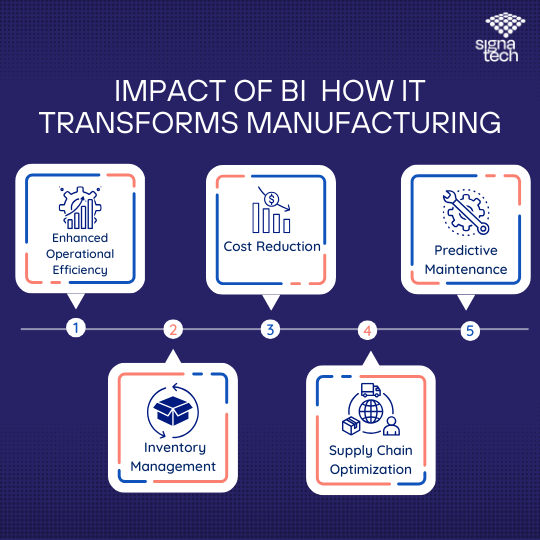

Impact of BI: How It Transforms Manufacturing

BI tools bring a transformative shift to manufacturing, offering several measurable benefits:

- Enhanced Operational Efficiency

BI assists the manufacturers to monitor their operations in real-time, identify issues and enhance the manufacturing process. - Cost Reduction

BI assists in identifying waste in energy consumption, labor time, and material consumption, all of which reduces avoidable costs. - Predictive Maintenance

With BI tools, sensors and IoT devices can predict equipment failures and hence minimize downtime and repair expenses. - Improved Inventory Management

Through business intelligence in manufacturing, it becomes easy to forecast demand and thus avoid cases of having excess stock which may be uneconomical. - Supply Chain Optimization

Manufacturers receive complete insight into their supply chains and can respond as necessary to disruption occurrences, demonstrating the critical role of Business Intelligence in Businesses Growth.

From Raw Data to Actionable Insights: The Process

The transformation of raw data into actionable insights involves several key steps:

Data Collection

Business intelligence in manufacturing platforms integrate data from several systems, which makes it easy to get a consolidated database.

Data Integration

BI platforms integrate data from several systems, which makes it easy to get a consolidated database.

Data Cleaning and Preparation

The collected data is cleaned to minimize general, sampling, measurement, and time-related errors in data analysis.

Data Analysis

Advanced analytical techniques such as machine learning and artificial intelligence algorithms, make pattern, trend and anomalies detection.

Visualization and Reporting

A dashboard and report are a form of data visualization that delivers information in an engaging and easily understandable way.

Actionable Insights

Understanding gained from this process allows manufacturers to make the right choices, enhance their procedures, and attain organizational efficiency.

BI Tools and Technologies for Manufacturers

Adopting the right BI tools and technologies is critical for success. Popular tools and their features include:

- Microsoft Power BI: Provides strong visualization and linking features.

- Tableau: Popular for its easy to navigate dashboard and easy to use interface.

- QlikView: Includes additional features for data search and analysis.

- SAP BusinessObjects: Suitable for big data analysis of large organizations and business establishments.

Manufacturers should also explore technologies related to business intelligence in manufacturing, such as Internet of Things-connected BI platforms, predictive analytics, and cloud BI solutions for flexibility and scalability.

Many experts now refer to Business Intelligence as BI imperative, a tool that has become mandatory for manufacturers that want to succeed in the current world. With the help of BI, manufacturers can transform their data into useful information that will help overcome some challenges and reveal new opportunities for development. From managing internal processes to improving the supply chain, to cutting expenses, BI helps manufacturers to remain competitive.

Are you prepared for a Business Intelligence revolution in your manufacturing processes? Get in touch with Signatech today to find out how our Business Intelligence Consulting Services and customized BI solutions will transform your success.